|

April 2016

Anyway, in 2013 I lost the home in Green Haven and the shop was dismantled and shoved into a 13 x 20 foot garage. For three years to get anything done I either had to shoehorn myself into the place or drag it's contents out onto the driveway to make space. This is the year that all changes, or I die trying. Anybody's bet which way that one falls. The garage has about 73 square feet less floor space than the old place did. This means EVERYTHING has to be on wheels so it can be moved out of the way when not in use. The table-saw got retracable wheels a few years back.

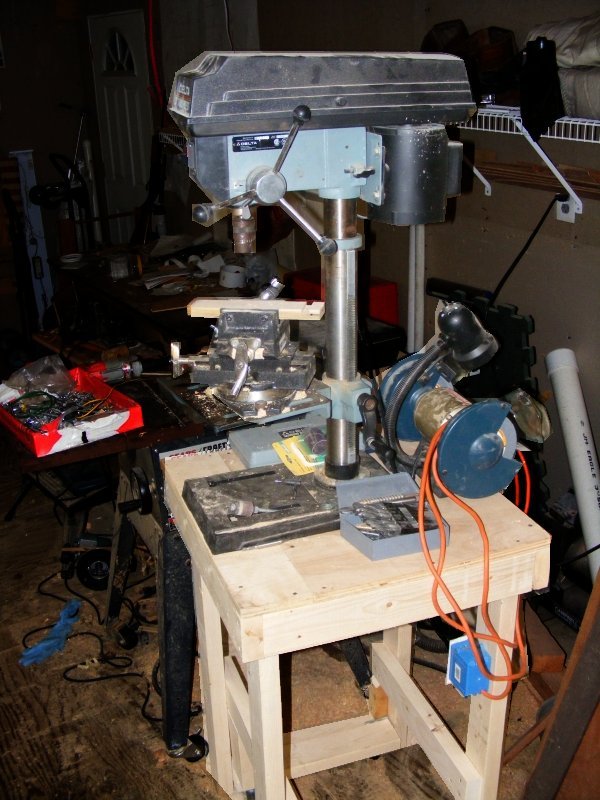

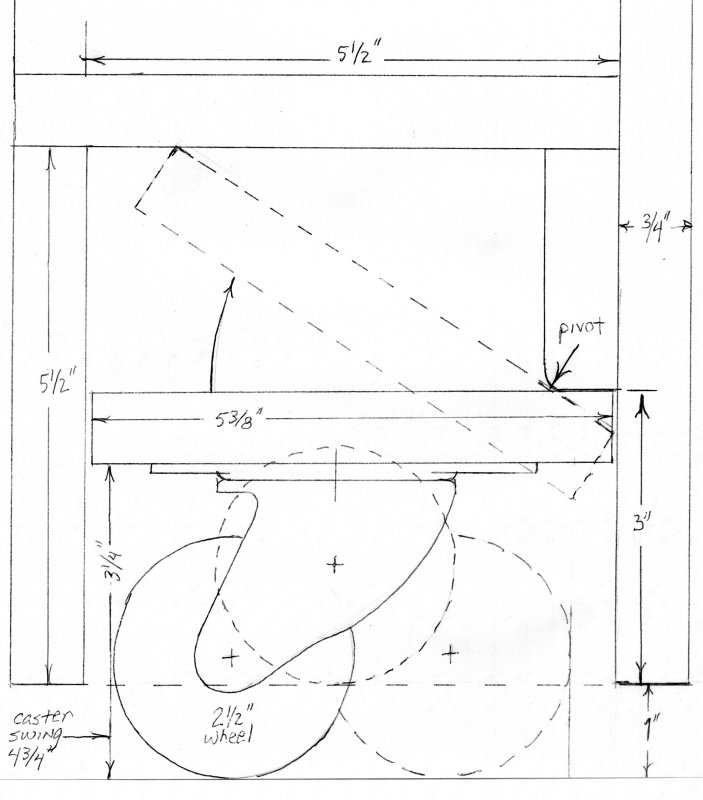

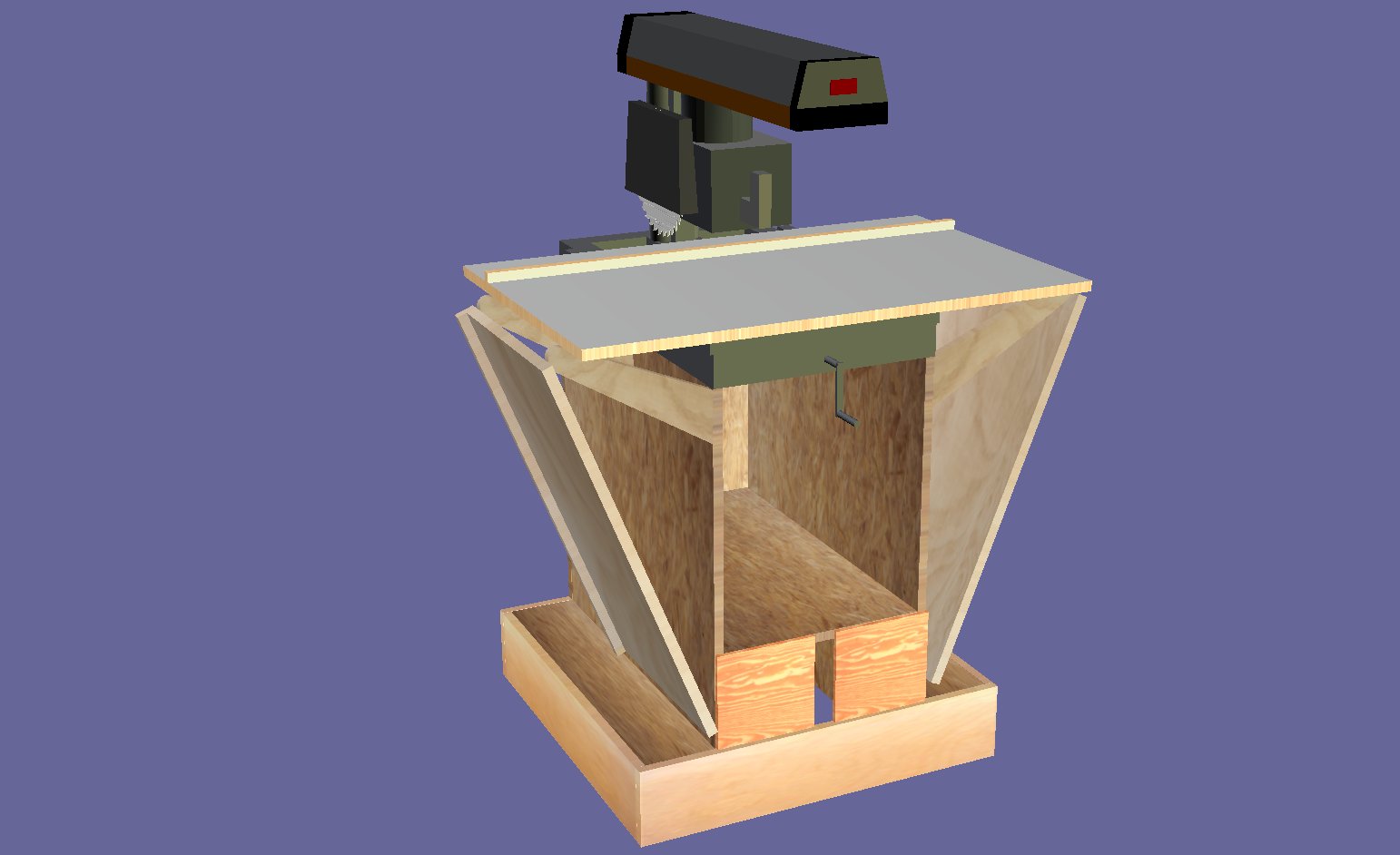

The arm saw, which was in a fixed position in the old shop, with work benches on either side; was mounted on a mobile base with retractable casters. It will get "wings" that fold down on either side. The casters are set up on the arm saw based on ideas I saw on one of Carl Holmgren's youtube videos. This design doesn't require hinges for the caster board to pivot on, saving some money. He has several videos regarding his shop that are definately worth checking out. Carl Holmgren Woodworking YouTube Channel The bandsaw got wheels at last. It's very top-heavy and near impossible to move without wheels. The picture shows it in the old shop.

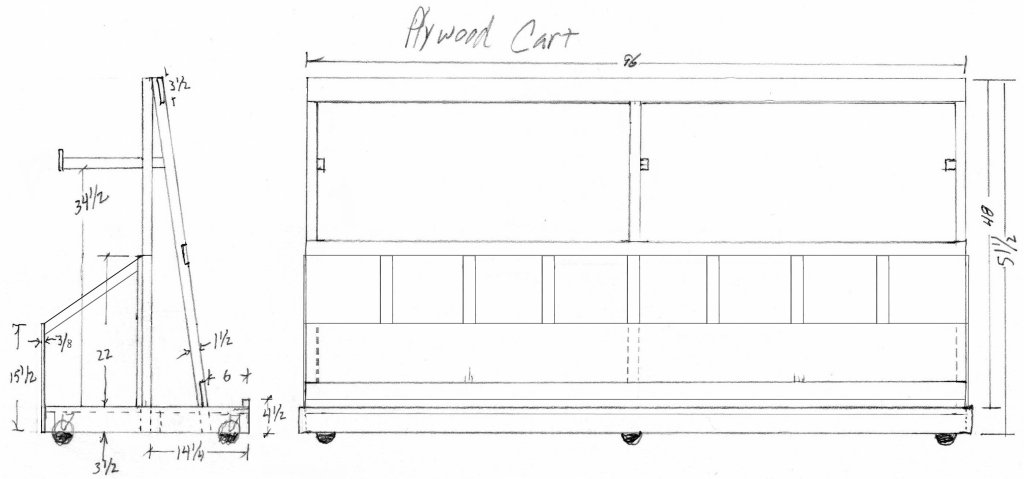

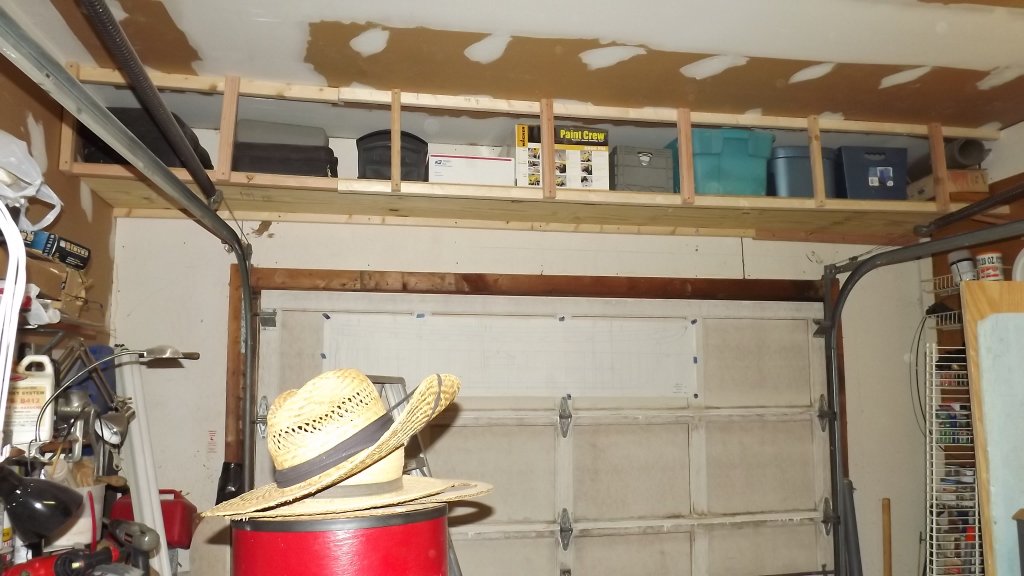

To get the sheet materials and cut-offs off the floor and organized, I built a cart to hold it all. The wheels on this don't need to be retractable, but there are six of them... As the tools are mounted on mobile bases, new shelving will get installed. A shelf in the dead space over the garage door will get installed next, as well as a way to hang my ladders on the ceiling above the garage door. A cross-piece will get mounted on the garage door tracks so a 4' flourescent shop-light can be mounted over the space without interferring with the garage door's operation. The garage door is the SE wall of the garage/shop. The NE wall currently has shelving, but the supports are weak and they're mounted too low since I intend to roll most of the tools up against that wall. These will be replaced with stronger shelves set a little higher and with an additional shelf above to use all the space. A dust-collection system based on a Shop-Vac will live in the corner of the SE and NE walls. At the other end of the NE wall an electrical sub-panel will be installed to power the shop, a 3' by 5' tall shelving unit that's something akin to a spice-rack will be mounted on the wall to hold all the plastic jars I keep fasteners in. The sheet-cart will usually live along the SW wall of the garage, under the one window in the shop. In the South corner of the shop there's already floor to ceiling pegboard about 3 foot wide; I'm leaving that in place. The other end of that wall will have a shelf speciffically to hold two of my models; Constellation and Pride of Baltimore. There's a built-in plywood and 2x4 bench on the NW wall to the left of the door into the house; that is coming out and shelving will go up on this wall as well. I have a 2' x 5' ish, bit of partical-board that was once a section of closet divider removed during a remodel almost 30 years ago, it's evolved into a roll-around work-table with retractable casters and the star of my first ever youtube video. It's gotten a drawer and some sanding and painting and served as a base upon which I built all three model ships.

Alas, the old work table's destined to be scrapped and replaced by a 4' x 6' roll-around work table with retractable casters, storage, and power! This is only in the design stage at the moment, as there's no where yet to put it.

It may appear that I could have gone lower with the shelf, but the top panel of the garage door actually only clears it by an inch. Another day and a little more done. The arm saw's base got a shelf and the front enclosed. These panels are more for keeping the lifting level from moving side-to-side. Having moved things out of the way I took pictures of the band saw on it's base. I also did some video of the operation of both which I'll post later. The rest of the time was spent going though things, sorting tools and fasteners out of "junk boxes;" condensing things from multiple containers into one, etc etc. Some picture from reenacting days were hung up just to get them out of the way and somewhere safe. The old half-model of my boat, which is in some need of repair after some 39 years or so, got attached to a bit of luan and mounted on the wall for the time being. I made a little video of the caster system I'm using for the tool bases and work-table...

One set of shelves were taken down and I designed their replacements. Hopefully I have enough plywood to make the supports. I did have enough plywood for all 48 supports. Used scraps from the boat Mark built at the old shop. Ripped some 2x6's down to 2x2's and mounted 4 standards on the wall. Notched three of the shelf boards around the 2x2's; reusing the shelf-boards that I just took down. Next step is to clear the second set of shelves and get those up. The lower portion of the 2x2's where there seems to be a shelf missing is where peg board will be going. Got the rest of the shelves up, and the peg-board underneath. I basically threw everything up on the shelves and peg-board to rid myself of more boxes and clutter on the floor; I'll reorganize and rearrange this area later. The left over bit of peg-board was mounted beside the house door. Trying to work out how the wings will function on the arm-saw. I want them attached to the base, not the saw table, so when I eventually replace the table, I don't need to disconnect the wings or anything else. Table of Contents:

|

||||

July 25 2016 | ||||